Products

Case

Contact SU SHI

Service Hotline 0755-27291255

Fax0755-27293730

E-MAIL: sushirechuli@163.com

CompanyAddress: 14 BaiSha Road,Second Industrial Zone,Shenzhen manholeNewbridge

Editor: Date:2014-07-01 17:57:21 Views:23637

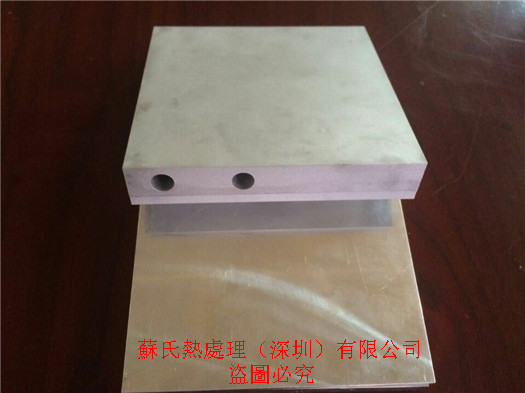

Magnesium alloy after solid solution treatment without artificial aging can increase the tensile strength and elongation, and obtain the maximum toughness and impact resistance. Due to slow diffusion of alloy magnesium alloy elements, and therefore requires a longer heating time to ensure the full solid solution strengthening phase. Magnesium alloy sand thick walled casting solution for the longest time. The second is thin-walled castings or metal mold casting, magnesium alloy is the shortest. The diffusion of alloy elements and phase decomposition process is slow, so the quench sensitivity of magnesium alloy low, quenching without rapid cooling, cooling airflow in the still air or forced flow in the artificial. But the vast majority of magnesium alloy is not sensitive to the natural aging, after quenching can keep at room temperature solid state for a long time.

| Prev: Prevention of quenching distortion and cracking measures | Next: Su's heat treatment to teach you about heat treatment technology of bearing from four aspects |

-

1

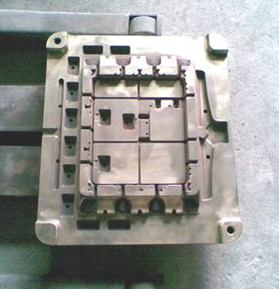

Brazing of aluminum frameProduct:Brazing of aluminum frame

Similar Articles

- Welding transverse crack reason mainly has the following several aspects

- Prevention of quenching distortion and cracking measures

- Magnesium alloy solid solution treatment

- Su's heat treatment to teach you about heat treatment technology of bearing from four aspects

- Pre-hardened mold material

- Mold surface treatment technology

- Hydrogen embrittlement

- Decarbonization and oxidation

- Heat treatment of non-magnetic die steel

Latest News

- Welding method of cast iron parts

- Reduce large structure welding deformation technological countermeasures

- Welding history

- Laser spot welding technology is analysed

- The way to prevent the welding spatter

- Titanium alloy laser repair welding technology

- The welding of titanium alloy and testing

- The point of use of stainless steel electrode should notice

- Welding transverse crack reason mainly has the following several aspects

- The role of argon gas in welding

History

- None

Su's heat treatment (Shenzhen) Co., Ltd. Guangdong ICP No. 14020634

service hotline: 0755-27291255

Fax: support for 0755-27293730

E-MAIL:sushirechuli@163.com

Company address: Shenzhen, Baisha bridge Second Industrial Zone No. 14