Products

Case

Contact SU SHI

Service Hotline 0755-27291255

Fax0755-27293730

E-MAIL: sushirechuli@163.com

CompanyAddress: 14 BaiSha Road,Second Industrial Zone,Shenzhen manholeNewbridge

Editor: Date:2014-05-05 13:59:11 Views:5356

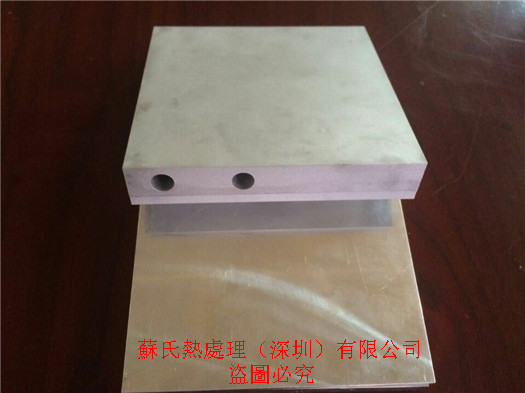

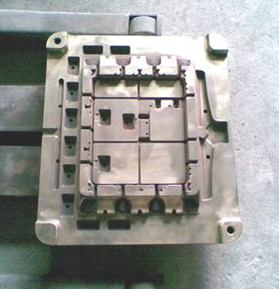

Vacuum heat treatment technology is developed in recent years, a new type of heat treatment technology, it has the characteristics of it is desperately needed in the mould manufacturing, such as preventing heating oxidation and decarburization, vacuum degassing and degassing, eliminate hydrogen embrittlement, so as to improve the plasticity and toughness of materials (parts) and fatigue strength. vacuum heating slowly, parts smaller temperature difference between inside and outside factors, determines the parts and small deformation caused by vacuum heat treatment process.

mold is mainly used in the vacuum heat treatment is vacuum oil cold hardening, vacuum air cooled vacuum quenching and tempering. to maintain the artifacts, such as mold excellent characteristics of vacuum heating and cooling agent and the choice of cooling process and is very important, die quenching process mainly adopts oil cooled and air cooled. machining of mould for after heat treatment is no longer working face, as far as possible by vacuum tempering after quenching, vacuum quenching workpiece (mould), in particular, it can improve the surface quality, related mechanical properties, such as fatigue, surface brightness, corrosion resistance, etc.

heat treatment process of the successful development and application of computer simulation technology, that makes it possible to mold the intelligent heat treatment. due to the mold production of small batch (even piece), the characteristics of many varieties, as well as to the performance requirements of high heat treatment and are not allowed to appear the characteristics of the waste, and makes mould intelligent heat treatment must be. foreign developed countries, such as the united states, japan, etc., in terms of vacuum high-pressure gas quenching, development is fast, the main target is mold.

| Prev: Overheating | Next: Pre-hardened mold material |

-

1

Brazing of aluminum frameProduct:Brazing of aluminum frame

Similar Articles

- Welding transverse crack reason mainly has the following several aspects

- Prevention of quenching distortion and cracking measures

- Magnesium alloy solid solution treatment

- Su's heat treatment to teach you about heat treatment technology of bearing from four aspects

- Pre-hardened mold material

- Mold surface treatment technology

- Hydrogen embrittlement

- Decarbonization and oxidation

- Heat treatment of non-magnetic die steel

Latest News

- Welding method of cast iron parts

- Reduce large structure welding deformation technological countermeasures

- Welding history

- Laser spot welding technology is analysed

- The way to prevent the welding spatter

- Titanium alloy laser repair welding technology

- The welding of titanium alloy and testing

- The point of use of stainless steel electrode should notice

- Welding transverse crack reason mainly has the following several aspects

- The role of argon gas in welding

History

Su's heat treatment (Shenzhen) Co., Ltd. Guangdong ICP No. 14020634

service hotline: 0755-27291255

Fax: support for 0755-27293730

E-MAIL:sushirechuli@163.com

Company address: Shenzhen, Baisha bridge Second Industrial Zone No. 14