Products

| Vacuum brazing | |

|

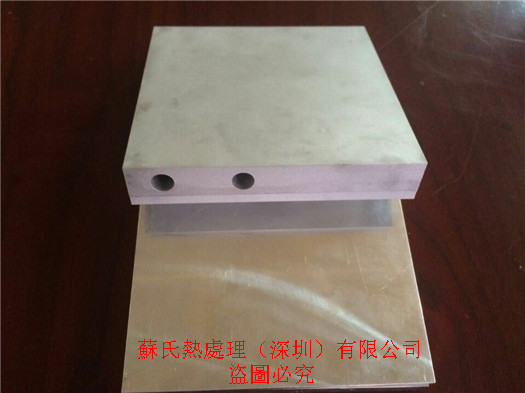

Vacuumbrazing,meansheating the workpiecein a vacuum chamber, with the mainrequirementsfor thewelding of high-quality productsand ease ofoxidation of the material.Vacuumbrazingfurnaceincludes acylindrical side wallofthe pressure vesseland the gatesize andposition of the dooris designed to beclosedat one endof the cylindricalsidewall.A workpiecehandling systemmounted onthe pressure vesseldoorfor supportinga workpieceof metalorbrazingheat treatment.Work processingsystem comprises arotatableworkpiecein the processapparatus.Vacuum systemmay be connectedto the workpiece,the workpieceis lower thanatmosphericpressure insidethebrazingprocess. |

|

Vacuum brazing , means heating the workpiece in a vacuum chamber , with the main requirements for the welding of high -quality products and ease of oxidation of the material . Vacuum brazing furnace includes a cylindrical side wall of the pressure vessel and the gate size and position of the door is designed to be closed at one end of the cylindrical sidewall. A workpiece handling system mounted on the pressure vessel door for supporting a workpiece of metal or brazing heat treatment . Work processing system comprises a rotatable workpiece in the process apparatus . Vacuum system may be connected to the workpiece , the workpiece is lower than atmospheric pressure inside the brazing process.

Vacuum brazing technology 1940s and since then has become a very promising welding technology . First appeared in the electronics industry brazing copper and stainless steel parts , and later applied to the aviation industry , nuclear industry , beginning in 1959 applied to the manufacture of stainless steel plate-fin heat exchanger. Now, are widely used in air separation equipment , petrochemical equipment , construction machinery , vehicles , boats and appliances and other industrial sectors of plate-fin heat exchanger and cooler.

As the vacuum brazing technology has unparalleled advantages , so the industrial countries in the world, the rapid development and wide application.

1 . Vacuum brazing , because without brazing agent, significantly improved the corrosion resistance of the product , eliminating the various forms of pollution , pollution treatment equipment costs , a good safety conditions ;

2 . Vacuum brazing is not only save a lot of expensive metal brazing agent , and also does not require complex flux cleaning process , reducing the cost of production ;

3 . Vacuum brazing brazing material wettability and good mobility , can weld more complex and narrow channel devices, vacuum brazing to improve the yield of the product, get strong clean work surface ;

4 . Long life as compared with other methods, the internal structure of the furnace and fixtures , can reduce the maintenance costs of the furnace ;

5. Vacuum brazing material for many , such as: aluminum , aluminum alloy, copper , copper alloy, stainless steel , alloy steel, low carbon steel, titanium, nickel , Inconel (Inconei) and so can be in a vacuum electric furnace brazing , according to the designer to determine the required use of brazing material of the device, wherein the aluminum and aluminum the most widely used .

Su's heat treatment Co. Ltd. was founded in 1990, after decades of development, scale is continually expanding, is located in Shajing Town Baoan District Shenzhen City Bridge second industrial zone, covering an area of 3000 square meters, the main business is to take all the metal, alloy steel, beryllium copper, heat treatment of high speed steel, cryogenic treatment (-196 C), nitrogen gas, liquid nitrogen, QPQ salt bath production line, high-frequency quenching, blackening and carburizing, the surface of hard and stainless steel processing.

The company is equipped with power of heat treatment technology, established a perfect quality testing equipment, equipped with vacuum quenching furnace, vacuum furnace, pit furnace, furnace, liquid nitrogen atmosphere furnace, rotary furnace, large mesh belt furnace, improve metallographic inspection equipment, material failure analysis, scientific management and complete, rigorous technology, skilled operation.

Company will be excellent quality and perfect service, and actively challenge, satisfy customer demand, has passed ISO9001:2000 in 2003 September (SGS) international quality certification. Has now become a reputable manufacturers.

Su's heat treatment (Shenzhen) Co., Ltd. Guangdong ICP No. 14020634

service hotline: 0755-27291255

Fax: support for 0755-27293730

E-MAIL:sushirechuli@163.com

Company address: Shenzhen, Baisha bridge Second Industrial Zone No. 14