Products

Case

Contact SU SHI

Service Hotline 0755-27291255

Fax0755-27293730

E-MAIL: sushirechuli@163.com

CompanyAddress: 14 BaiSha Road,Second Industrial Zone,Shenzhen manholeNewbridge

Editor: Date:2014-08-22 16:22:47 Views:5643

(1) hollow cathode ion nitriding technology can effectively Nitriding on the workpiece, can avoid generating arc and damage the test piece surface smooth degree of danger.

(2) hollow cathode ion nitriding technology at very low pressure (100~150Pa) of nitriding case, reduces the use amount of ammonia. To save energy, reduce pollution.

(3) hollow cathode ion nitriding technology, the sample can be neutral, surface strengthening processing of 40Cr steel, under the optimum conditions, the thickness of compound layer is about 2um, the thickness of the nitrided layers can reach 200um, the surface hardness is two times higher than the body.

(4) 40Cr steel hollow cathode ion nitridation, the most suitable processing temperature should be 500 ℃, the most suitable time of treatment should be about 6H.

-

1

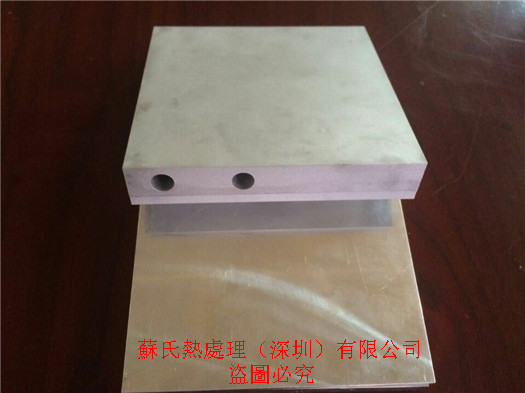

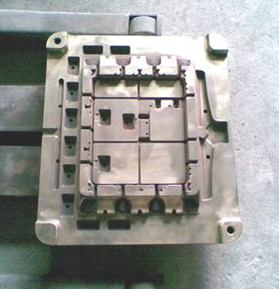

Brazing of aluminum frameProduct:Brazing of aluminum frame

Similar Articles

- Welding method of cast iron parts

- Reduce large structure welding deformation technological countermeasures

- Welding history

- Laser spot welding technology is analysed

- The way to prevent the welding spatter

- Titanium alloy laser repair welding technology

- The welding of titanium alloy and testing

- The point of use of stainless steel electrode should notice

- The role of argon gas in welding

- The impact of high temperature alloy welding

Latest News

- Welding method of cast iron parts

- Reduce large structure welding deformation technological countermeasures

- Welding history

- Laser spot welding technology is analysed

- The way to prevent the welding spatter

- Titanium alloy laser repair welding technology

- The welding of titanium alloy and testing

- The point of use of stainless steel electrode should notice

- Welding transverse crack reason mainly has the following several aspects

- The role of argon gas in welding

History

Su's heat treatment (Shenzhen) Co., Ltd. Guangdong ICP No. 14020634

service hotline: 0755-27291255

Fax: support for 0755-27293730

E-MAIL:sushirechuli@163.com

Company address: Shenzhen, Baisha bridge Second Industrial Zone No. 14